3 Types of Cathodic Protection

In our modern age, the integrity and longevity of infrastructural assets are more crucial than ever. Structures such as pipelines, tanks, and marine vessels are continuously at the mercy of corrosion, a natural process that can lead to costly failures. As a leading figure in the corrosion prevention industry, Qualcorr is at the forefront of employing cathodic protection, an efficacious method to curb this relentless phenomenon. In this article, we explore the varied types of cathodic protection techniques that Qualcorr harnesses to safeguard infrastructural assets.

1. Sacrificial Anode Cathodic Protection (SACP):

A time-tested approach, SACP involves the use of anodes made of metals that are inherently more “active” in electrochemical series than the structure it aims to protect. The underlying principle is quite straightforward: these anodes willingly “sacrifice” themselves by corroding preferentially, thereby preserving the integrity of the protected metal.

Materials Commonly Used:

- Zinc: Popularly used for protecting structures in saltwater.

- Magnesium: Often the preferred choice for structures in soil or freshwater environments.

- Aluminum: Favoured for its efficiency and lifespan, especially in marine environments.

While SACP is a self-operating system, it’s imperative to monitor and eventually replace these anodes as they deplete over time. Qualcorr, with its extensive experience, ensures not just the correct placement and utilization of these anodes but also their periodic inspections and replacements, providing a seamless protection service.

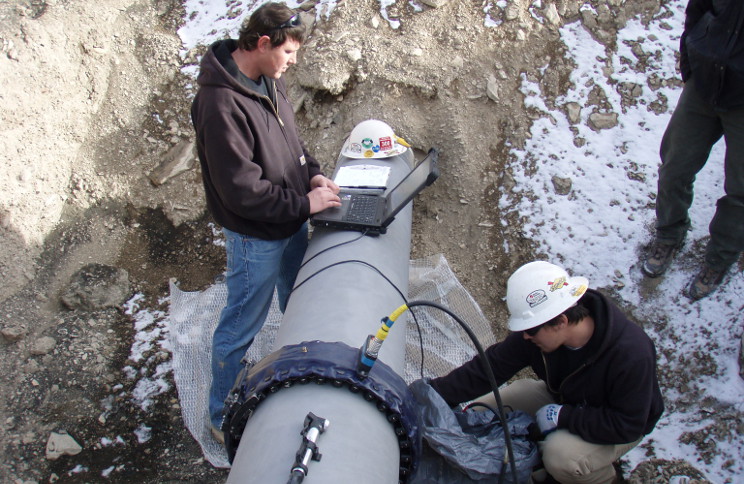

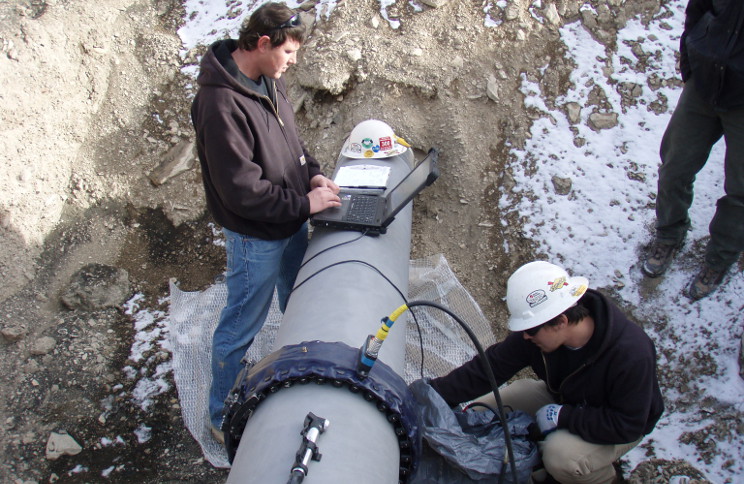

2. Impressed Current Cathodic Protection (ICCP):

When structures are vast, or when the demand for protection exceeds what sacrificial anodes can provide, ICCP emerges as the hero. This system employs an external power source that introduces a direct current into the structure. The structure becomes the cathode and is thus protected from corrosion, while the anodes attached to the power source remain relatively unscathed due to their inert nature.

Inert Anodes Used:

- Mixed Metal Oxide (MMO): Known for its high current capacity and long operational life.

- High Silicon Cast Iron: Famed for its durability and resilience.

One of the significant advantages of the ICCP system is its controlled nature. Qualcorr’s expert engineers meticulously design these systems, ensuring optimal current distribution across the protected structure, minimizing potential hotspots of corrosion.

3. Remote Cathodic Protection:

Sometimes, for reasons ranging from environmental considerations to interference concerns, anodes cannot be placed directly alongside the structure. Here, remote cathodic protection comes into play. By placing anodes at a strategic distance, Qualcorr ensures optimal current distribution while circumventing potential issues linked with proximate placement. This technique combines the principles of both SACP and ICCP, depending on the specific requirements of the project.

Advantages of Remote CP:

- Environmental Sensitivity: Helps in avoiding ecological disturbances in certain zones.

- Optimal Current Distribution: Assures uniform protection across the structure.

- Ease of Maintenance: Strategic placement can make maintenance more straightforward.

In the universe of corrosion prevention, Qualcorr remains a beacon of trust, harnessing the full spectrum of cathodic protection techniques. With a deep understanding of the science behind corrosion and its prevention, Qualcorr not only implements these systems but also provides regular monitoring, ensuring that structures remain shielded against the relentless tide of corrosion for years to come.

Looking Back: Types of Cathodic Protection

In conclusion, while corrosion is an inevitable natural process, with the right expertise and techniques, it can certainly be kept at bay. And in this battle against corrosion, Qualcorr stands as a steadfast ally, blending science with experience, ensuring the durability and safety of invaluable infrastructural assets.